Primacon PFM 24 CC - CompactCell

Automated Micro-Precision Milling Cell

TECHNICAL DETAILS

| Table Size | |

|---|---|

| Clamping Surface | 3-axis |

| X | 344 mm |

| Y | 295 mm |

| Z | 180 mm |

| Traverse | |

| X | 240 mm |

| Y | 240 mm |

| Z | 240 mm |

| B-Axis (Pivot Axis) | -120° bis +30° |

| C-Axis (Axis of Rotation) | 360° (endlos) |

| Feed / Rapid Traverse | |

|---|---|

| Linear Axis | 12 m/min |

| Pivot Axis B | 5.500 °/min |

| Rotary Axis | 21.600 °/min |

| Acceleration | |

|---|---|

| Linear Axes | 10 m/s² |

| B-Axis (Pivot Axis) | 4000 °/s² |

| C-Axis (Axis of Rotation) | 15.000 °/s² |

| CNC Control | |

|---|---|

| Heidenhain | TNC 640 |

| Position Accuracy | VDI/DGQ 3441 |

|---|---|

| Linear Axes | ±0.001/0.0005 P/Ps in mm |

| Squareness | 1 µm/100mm |

| Resolving Power | 0.1 µm |

| Working Spindle | |

|---|---|

| Speed Range | 500 - 80.000 U/min |

| Power | 4-6 KW |

| Toolholder | HSK F32 |

| Tool Changer | |

|---|---|

| Tool Places | 80 |

| Tool ø | 40 mm |

| Changing Time | 5 s |

| Tool Handling | Option |

|---|---|

| Tool Places | 25-120 |

| Changing Time | 5s |

| Miscellaneous | |

|---|---|

| Maschine Weight | 1500 Kg |

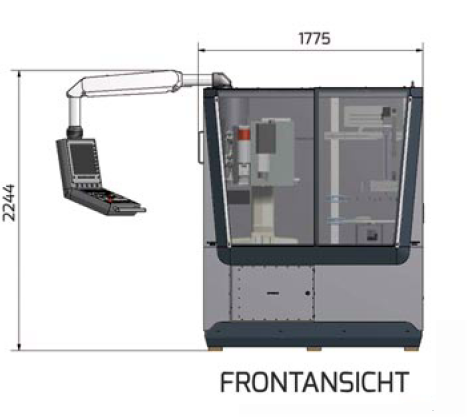

| Space required | 1.8 x 1.7 m² |

As a further development of the proven machine concept of the PFM 24 originated the CompactCell with automatic manufacturing cell and a micro precision for the most demanding applications . The CompactCell was designed for micron accuracy multilayer production of small workpieces and allows micro milling and guilloching in one machine. Moreover, also all proven options from the known PFM 24 product line are still available.

Air-Bearing High-Frequency Spindle

- Revolutions of 500 R / min - 80.000 R / min

- Dynamic Length Compensation

- Air bearing technology for the best surface finish

- No wear

Ergonomic Operating Concept

- Ultramodern machine control TNC 640 from Heidenhain

- Clear and User-Friendly

- Adjusts the largely automated operation

- Precise contour of the finished workpiece for machining at high speed

Double arm gripper on tool changer

- Tool changing magazine includes as standard 80 seats

- Reduction of the chip-to-chip times to 5 sec (tool changer and workpiece changer are equipped in parallel)

6-axis robot / pallet changer

- Integrated automation

- High degree of automation in a small space

- Direct handling of workpieces

- Automatic workpiece changer with 24-125 seats

More reasons to opt for our PFM 24 CC

Customized solutions possible due to the modular machine concept (3 to 5 axes)

Equipped with state-of-the-art high-tech components

High production quality - thus constant accuracy results on the workpiece

Reliability and longevity in 24 hours continuous operation

Consistent microprecision for many years

Low maintenance, thus high machine availability and low maintenance costs

User-friendly handling

Optimized access to CNC control and all control elements

Small foot print

Reduction of the processing time because of the new double arm gripper

Economical processing of any machinable material

Processing of dusty materials without retouching or upgrading the machine

Conventional clamping systems (System 3R, Erowa) can be implemented

3D probe for workpiece measurement in the machine (without clamping)

Laser tool measurement (dirt-insensitive); By smaller focus point more accurate results

Minimum quantity cooling lubrication system, full jet lubrication or cold air nozzle

Optimized temperature management system with 0.1 Kelvin hysteresis

Zero point stability - Cooling of all heat-emitting elements (milling spindle, motors, axes, control cabinet)